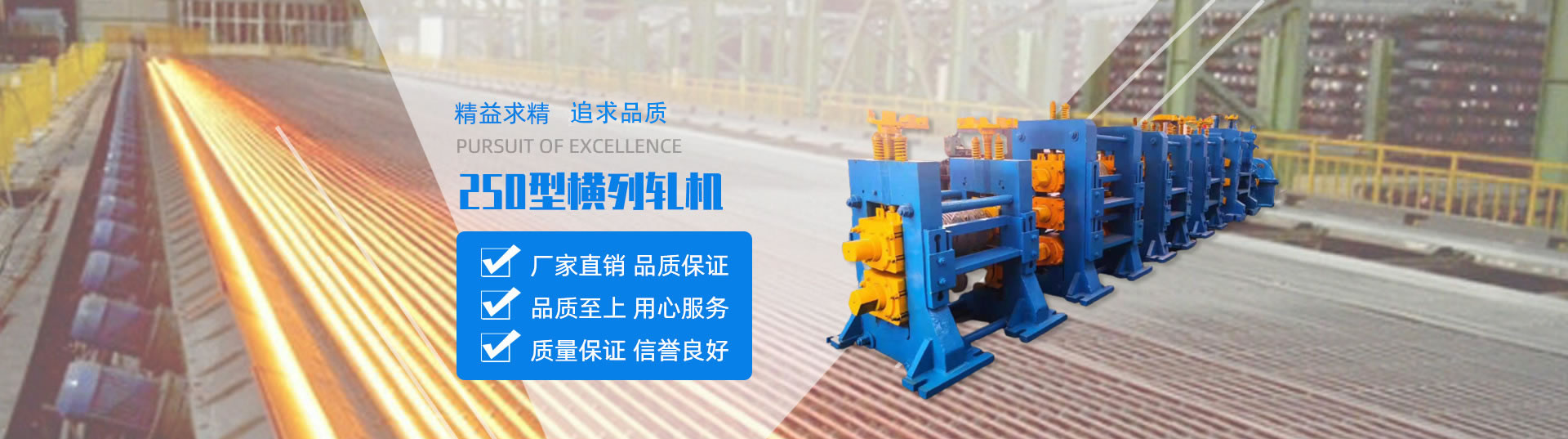

螺纹钢改制材生产线 Remolding steel production line

把废旧钢筋通过加热进行轧制成新的螺纹钢、圆钢、扁钢等再生材利用。

优势指南

1、能显着降低能耗,降低成本。热轧时金属塑性高,变形抗力低,大大减少了金属变形的热轧型钢能量消耗。

2、能改善金属及合金的加工工艺性能,即将铸造状态的粗大晶粒破碎,显着裂纹愈合,减少或消除铸造缺陷,将铸态组织转变为变形组织,提高合金的加工性能。

3、通常采用大铸锭,大压下量轧制,不仅提高了生产效率,而且为提高轧制速度、实现轧制过程的连续化和自动化创造了条件。

The waste steel bars are rolled into new regenerated materials such as rebar, round steel and flat steel by heating.

Advantage guide

1, can significantly reduce energy consumption, reduce costs. In hot rolling, metal plasticity is high and deformation resistance is low, which greatly reduces the energy consumption of hot rolled section steel.

2, can improve the processing performance of metal and alloy, that is, the casting state of coarse grain broken, significant crack healing, reduce or eliminate casting defects, the as-cast structure into deformation structure, improve the processing performance of alloy.

3, usually adopt large ingot, large reduction rolling, not only improve the production efficiency, but also to improve the rolling speed, continuous rolling process and automation to create conditions.