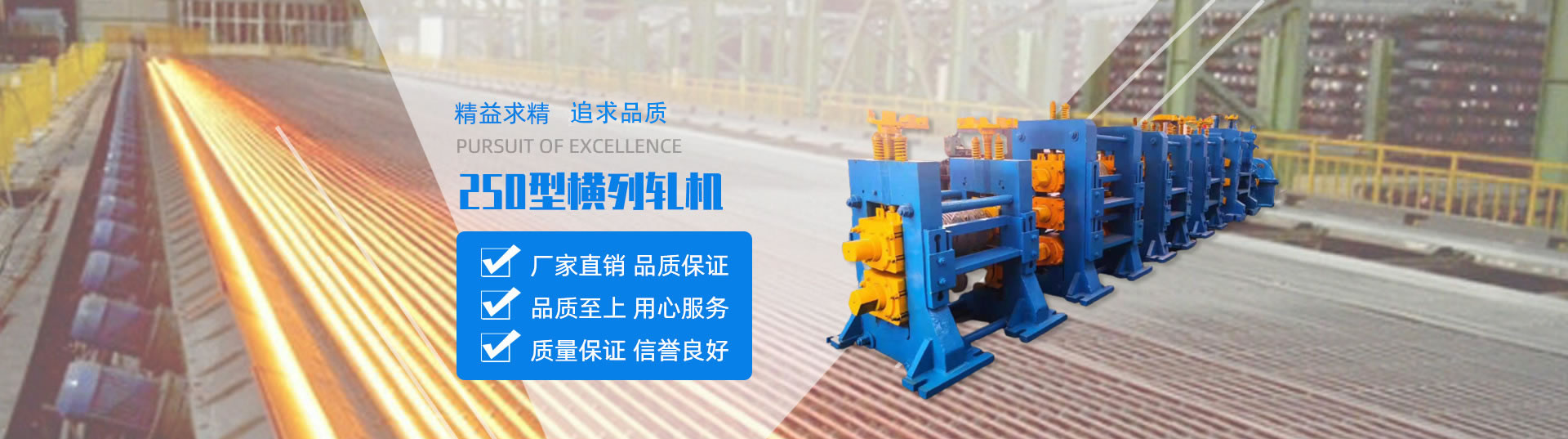

连轧圆钢生产线 Continuous round steel production line

圆钢连轧机组,包括成品轧机,所述成品轧机前设置有导卫,所述导卫前设置有规圆机,所述规圆机前设置有平-立交替向前布置的水平轧机和立式轧机。本实用新型在几乎不改动现有设备的情况下,通过轧制变形工艺的优化达到了提高产品精度的目的,具有投资少、实施简单的特点,轧制出的圆钢成品通根尺寸稳定、精度高、表面光洁度好,尺寸精度可达到国标甲等精度,解决了现有圆钢连轧机组因轧机装配精度和刚度差、轧机弹跳大、电控系统控制精度差而引起的圆钢通根尺寸不稳定、表面光洁度差的问题。

The round steel continuous rolling mill comprises a finished mill, the finished mill is provided with a guide before the guide is provided with a circular gauge machine, the circular gauge machine is provided with a horizontal rolling mill and a vertical rolling mill arranged alternately forward. The utility model almost does not change the existing equipment, through the optimization of the rolling deformation process to achieve the purpose of improving the accuracy of the product, has the characteristics of less investment, simple implementation, rolled out of the finished round steel root size stability, high precision, good surface finish, dimensional accuracy can reach the national standard A precision, etc. The problems of unstable dimension and poor surface finish of round steel through root caused by poor assembly accuracy and stiffness, big bounce of rolling mill and poor control accuracy of electric control system in the existing round steel continuous rolling mill are solved.